Description

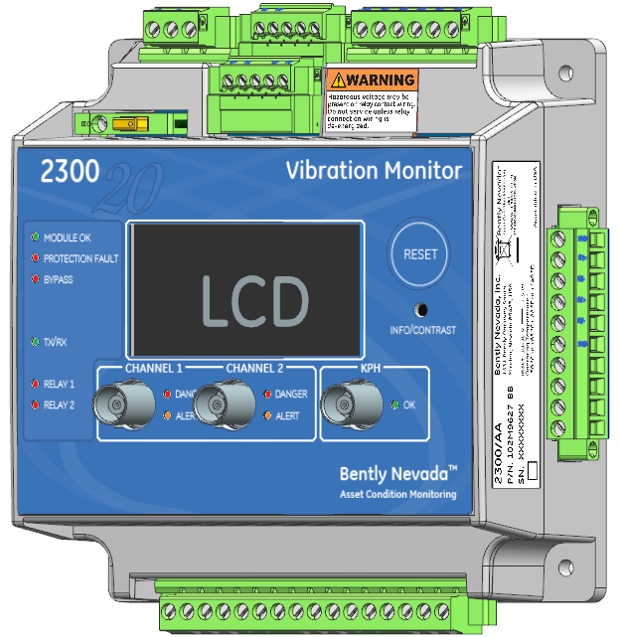

The 2300 Monitors feature two seismic channels and a speed channel, providing continuous monitoring and protection for BOP (Balance of plant) equipment. It is a perfect match for proactively managing your assets, rather than waiting until production outages to replace equipment.

The 2300 series monitors enable condition based monitoring and protection with support for various interfaces and functions. Inputs include seismic and speed transducers, and outputs include relays, buffered output, TCP/IP Ethernet, and an LCD display. This monitor is available with either 4-20 mA output (2300/20 1) or a TrendMaster SPA line interface (2300/25 2).

The 2300/20 Monitor can be used to replace legacy Bently Nevada monitors such as the 1900/27, but more importantly it is a full featured monitor for use in monitoring and protecting assets such as motors, pumps, and fans.

The monitor is software configurable, and includes configuration software. There is also an integrated LCD and multiple LEDs to show the channels’ real-time data and status locally.

Effective plant asset management, and particularly effective fleet management of machinery assets, often depends on remote access using condition monitoring software such as System 1* Evolution.

Monitor Key Features

2300/20

Two 4-20mA outputs Two relay outputs with programmable setpoints

Ethernet 10/100 Base-T communication for configuration using Bently Nevada Monitor Configuration software (included)

One dedicated speed and Keyphasor* channel supporting Proximity probes, Magnetic pickup and Proximity switch type sensors

Three buffered transducer outputs (including Keyphasor signal) providing short circuit and EMI protection. Buffered outputs for each signal are through BNC connectors

Continuous monitoring and protection

LCD display showing vibration amplitude, setpoints, and speed

Two acceleration inputs with synchronized sampling for advanced diagnostics

Key measurements(Direct 0-pk, pk-pk, Direct rms, Derived pk, integrated direct pk, Speed) real-time provided with alarm configuration

LEDs show the monitor status Local contacts for positive engagement of channel bypass, configuration lockout, and reset

Optional Modbus®1 over Ethernet

2300/25

Trendmaster SPA interface

Two relay outputs with programmable setpoints

Ethernet 10/100 Base-T communication for configuration using Bently Nevada Monitor Configuration software (included)

One dedicated speed and Keyphasor channel supporting Proximity probes, Magnetic pickup and Proximity switch type sensors

Three buffered transducer outputs (including Keyphasor signal) providing short circuit and EMI protection. Buffered outputs for each signal are through BNC connectors

Continuous monitoring and protection

LCD display showing vibration amplitude, setpoints, and speed

Two acceleration inputs with synchronized sampling for advanced diagnostics

Key measurements(Direct 0-pk, pk-pk, Direct rms, Derived pk, integrated direct pk, Speed) real-time provided with alarm configuration

LEDs show the monitor status Local contacts for positive engagement of channel bypass, configuration lockout, and reset

Optional Modbus®1 over Ethernet